RC respirators are ideal for the protection of the operators involved in

long duration works in chemical plants, polluted areas and, generally,

in all cases where there is, or may be, oxygen deficiency and long

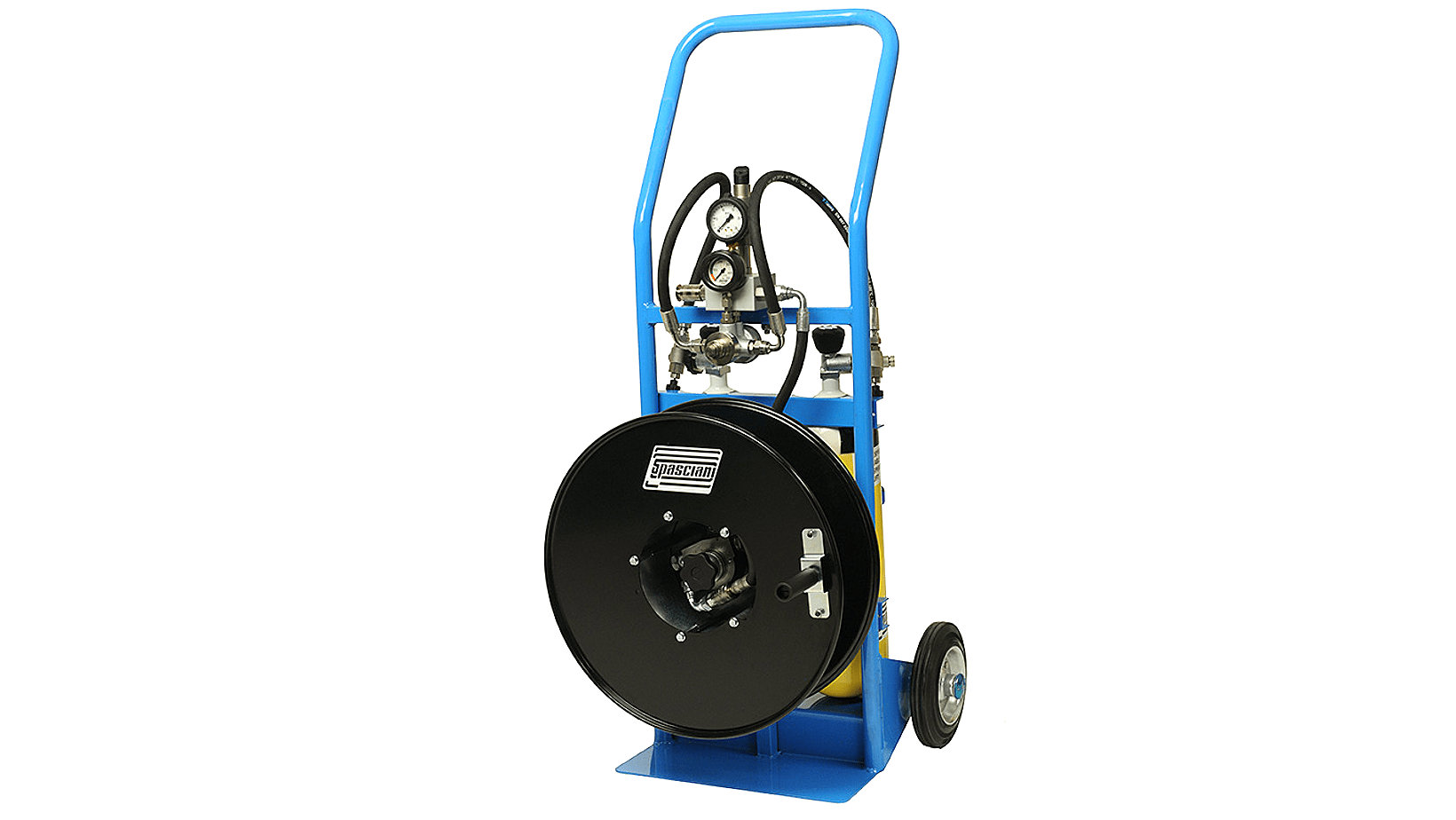

autonomy is needed. The compressed air line supply unit model RC

2603 is one of the main components of the breathing apparatus with

demand valve.

RC respirators are made of a mobile supply unit mounted on a trolley

able to feed, depending on the additional equipment required, up to

two operators at the same time at a max distance of 50 metres from

the cylinder. For every operator a medium pressure supply hose, a

carrying belt, a demand valve and a mask are required. The demand

valve, the mask and the general working principle of the reducer on

the supply unit are exactly the same used for Spasciani breathing

apparatus type RN and BVF and they bring back to the general description of the mk2 system.

RC 2603 supply unit is mounted on a two tyres trolley provided with

a reel for the tube. The trolley is also provided with the RB pressure

reducer, which maintains the outlet medium pressure constant independently from the pressure in the cylinder, two pressure gauges

that continuously read the high and medium pressure, the alarm whistle which activates simultaneously with the alarm on the demand

valve and a quick coupling for the connection of a tube for a second

operator. The trolley is provided with two high pressure tube to connect two 300 bar cylinders (to be ordered separately) equipped with

EN 144 valve. The high pressure tubes are provided with release

valves to replace cylinders when in use.

The connection of the feeding system to the demand valve is made by 8×17 medium pressure hoses available

in different lengths and provided with quick safety couplings to be ordered separately. Two hoses can be connected to the trolley, one by the reel and the other by the second coupling on the reducer. The medium pressure

hose shall be carried along by the user carried by the special carrying belt provided with snap hook.

The demand valve used in the RC respirators shall be type A or BN. The two types only differ for the connection

to the mask. Demand valve A type is provided with standard screw connector to EN 148-3 (M45x3) while type

BN is provided with snap in connector to DIN 58600. Type A demand valve may be used with TR 82 A or TR 2002

A masks while type BN only with TR 2002 BN.

In both models the positive pressure is automatically activated by the first breath in and maintained in the face

piece thus impeding any possible inlet of contaminated air from outside. In case of need the positive pressure

may be manually activated by a front button on the demand valve that also permit to have an extra flow.

The demand valve is connected to the medium pressure hose by means of a male quick coupling.

The masks that can be used on RC respirators are TR 82 A, TR 2002 A or TR 2002 BN (see specific data sheet

for the technical features). They must be compatible with the demand valve used.

The respirator takes advantage from the unique MK2 System warning built into the demand valve. This is activated when the pressure left in the cylinder drops below 35 bar. The signal originates from a sounding vibration

caused by every inhalation. In this way the full capacity of cylinder is made available to the user for breathing.

The acoustic warning is related to the respiratory frequency of the user and allows the user to distinguish his

own signal from that emitted by nearby fellows or noise (Self Test Function). The location of the warning device

protects it from frost or dirt.

RC respirators may be used in conjunction with back up self contained breathing apparatus BVF BU, connected

through a four-way valve and worn by the user. The breathing apparatus activates when for every reason the feeding from the air line system is interrupted and enable to get out from the dangerous area.

TECHNICAL DATA:

RB pressure reducer: piston with compensator

Demand valve: with integral alarm device and supplementary supply button

Setting of the alarm at the demand valve and at the trolley: 55 ± 5 bar

Volume/pressure of Cylinder: 6 l/ 300 bar

Number of cylinders: 2

Feeding hoses: diameter 8×17, available in different sizes (max 50 meters)

Air reserve: 3300 N litres

Duration: 110 min with an average consumption of 30 l/min and with one operator

CLASSIFICATION

Certified to EN 14593-1:2005 and meeting with the provision of Regulation (EU) 2016/425 and

MARKING

MATERIALS

Mask: See specific data sheet

Carrying belt: Self-extinguishing webbing and metal snap hook

Reducer: Nickel plated aluminium

Alarm and feeding block: Nickel plated aluminium

Automatic Demand Valve: Glass fibber reinforced nylon housing

Feeding hoses: Non-toxic SBR provided with special clamped quick connectors

Cylinder: Steel

STORAGE

Store at temperatures between -20 and +50 °C and with RH <80%

WEIGHT

50 Kg approx. with fully charged cylinders (without masks and hoses)

DIMENSIONS

530 x 500 x 116 mm

Reviews

There are no reviews yet.