Mobile Breathing Air Compressor Siting and Location

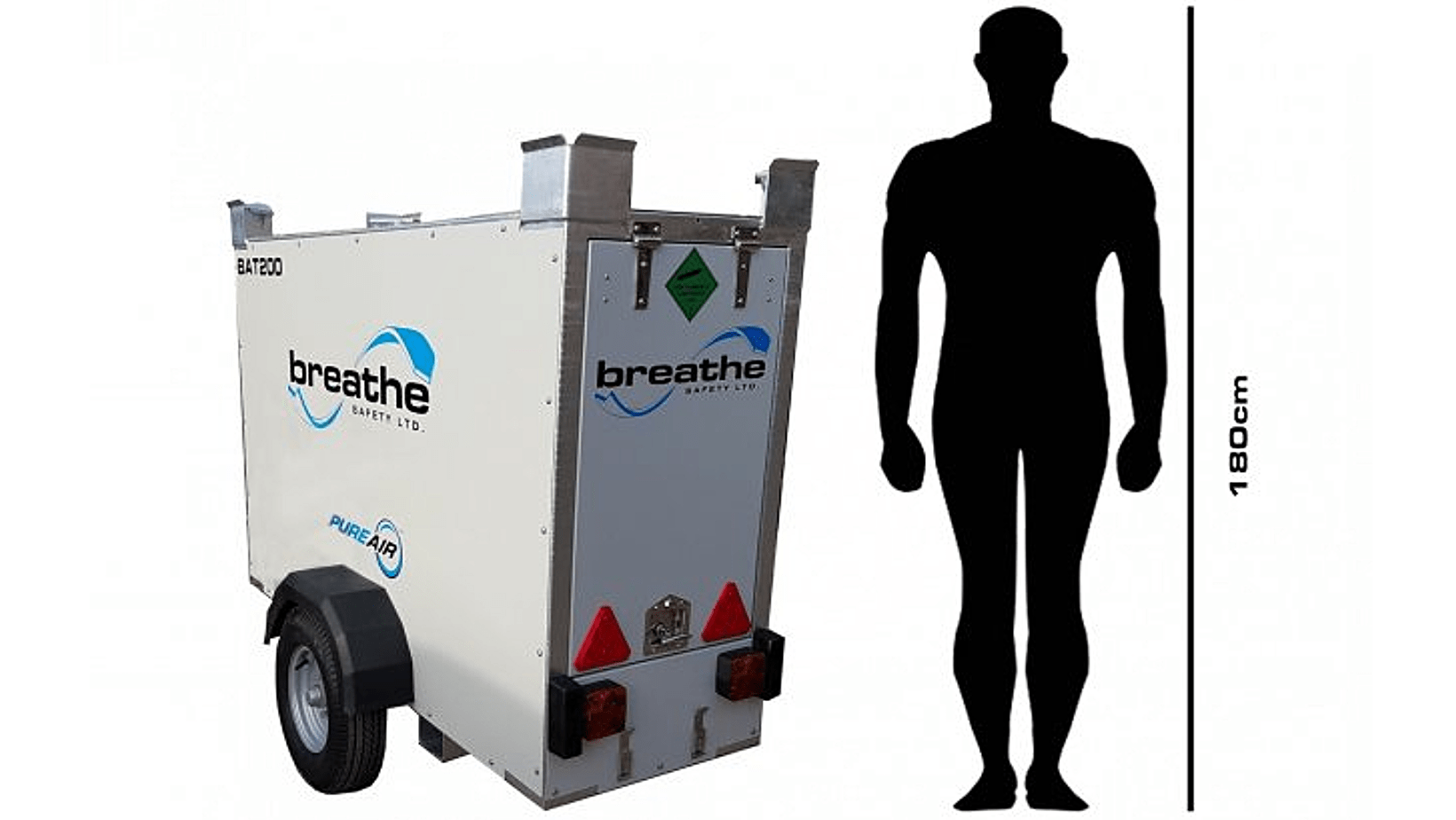

Breathing Air Compressors provide an excellent form of long duration breathing air supply. These units compress, clean and dry the surrounding air and feed it to the Breathing Air users, rather than regulating a high pressure cylinder bank to a pressure suitable for Breathing Apparatus as an Breathing Air Trailer does.

Compressors remove the need for refills, as required on an air trailer, and are often smaller and more portable as well. There are units on the market that incorporate a Chalwyn valve and spark arrestor, making them suitable for an even more extensive range of hazardous entries.

There is however an area that needs to be carefully considered when choosing a Breathing Air Compressor over an Air Trailer, and that is that toxic gases and fumes will not be cleaned by the compressor, and so it is therefore important to consider the following in your set up:

- Always use a compressor with an air intake that extends up away from the compressor – this means air will be drawn in from higher up away from exhaust and fume laying near the ground

- Make sure you do not set up your compressor where the exhaust of other plant will affect it – keep in mind items with high level exhausts or plant running in an enclosed area where fume could build up

- Check what is upwind and whether this could potentially compromise the air quality

Once you are happy with the set up then the unit should be Air Quality Tested to EN12021 by a qualified person. This will confirm that the air is suitable for breathing apparatus usage. When a compressor is re-sited then it should be air quality tested again.

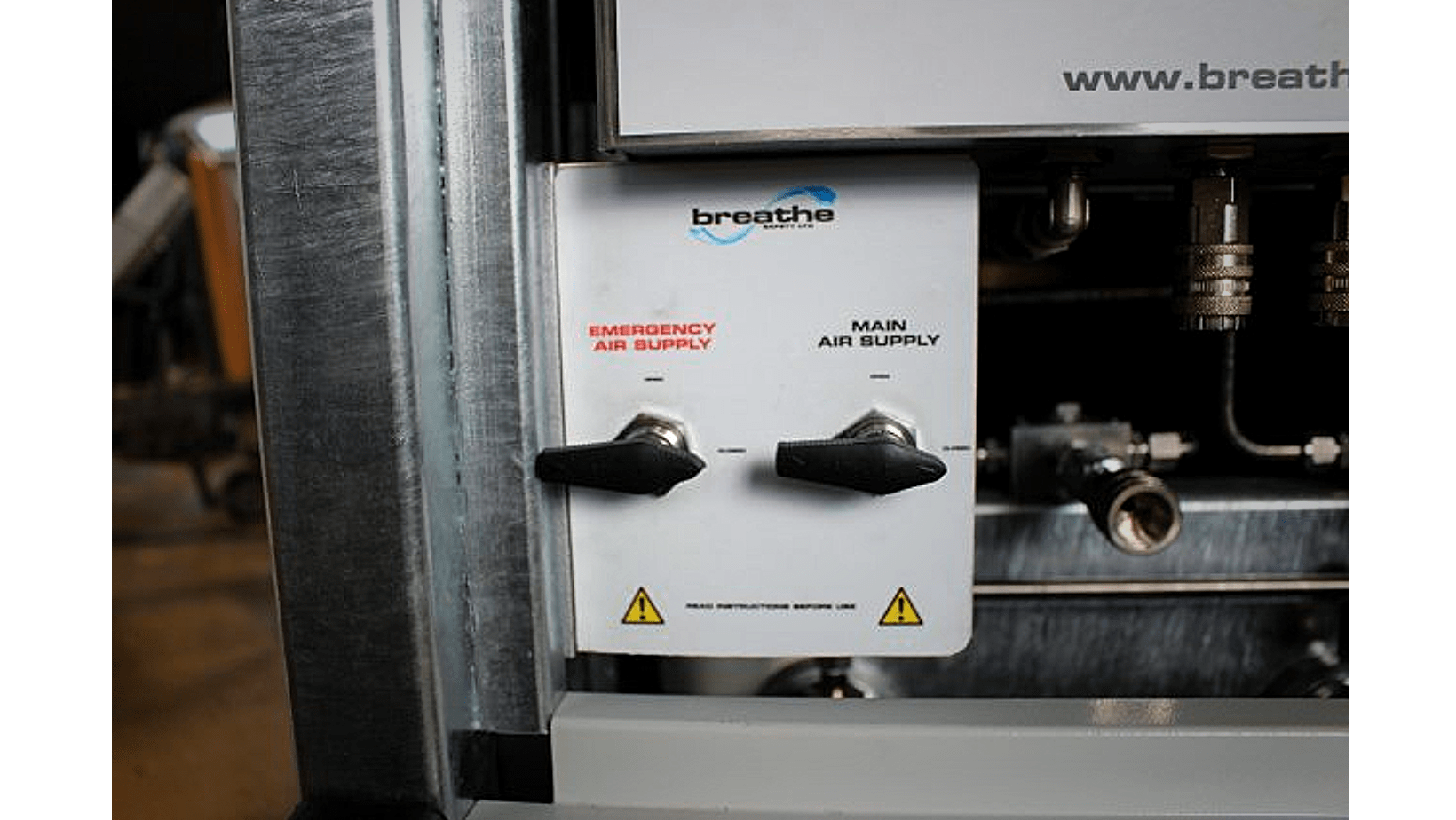

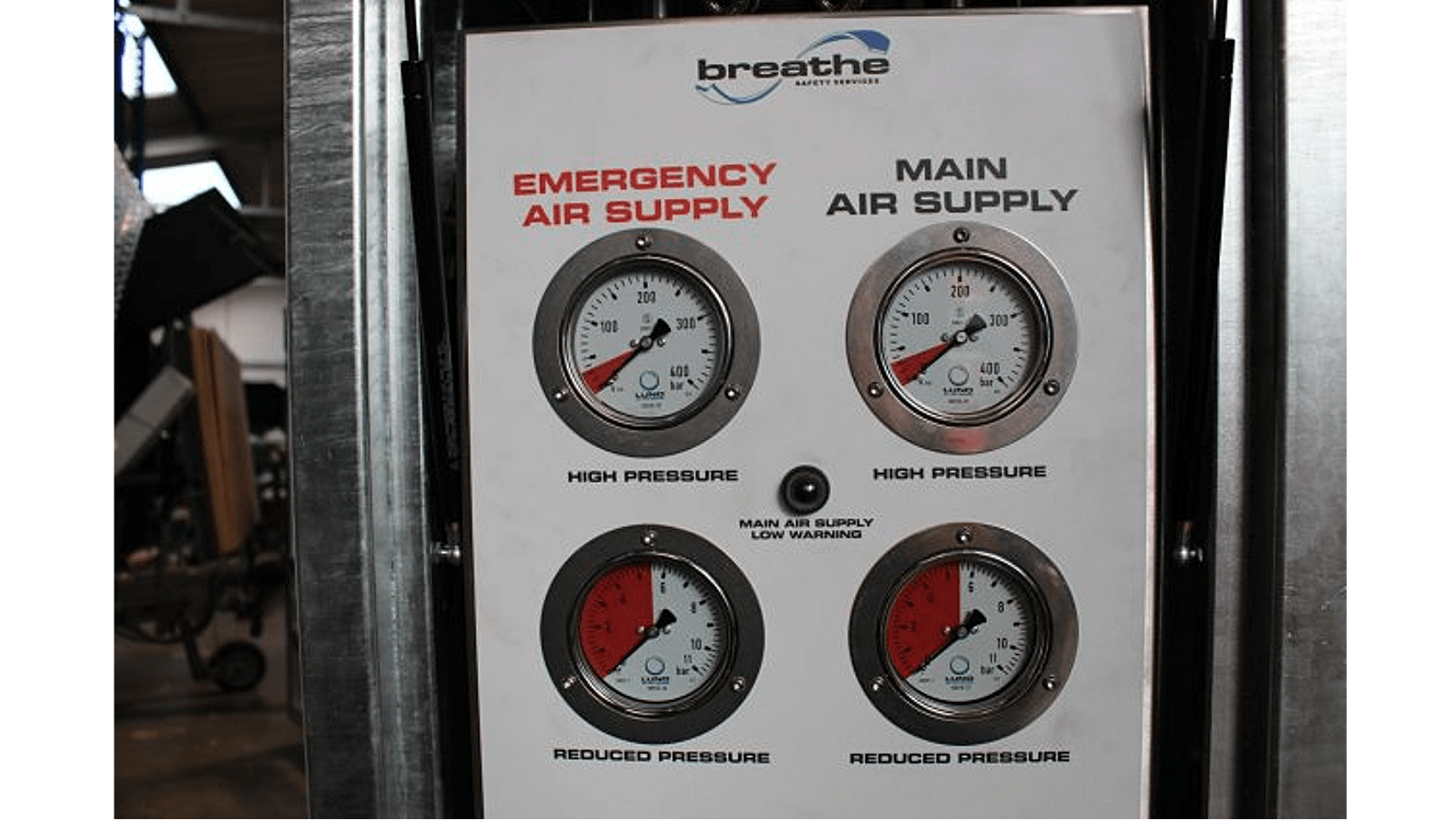

The compressor is now ready for use, but be sure that the Entry / Trailer Controller keeps an eye out for a change in conditions that could potentially affect the quality of the air supply and alerts the users as necessary. The Entry Controller can activate the Emergency Air Supply if they are concerned as to Air Quality and withdraw the entrants form the work area.

Make sure that any compressor that you are using for Breathing Air Supply is fully compliant and has an Emergency Air Supply to safely withdraw entrants from the work area in an emergency.

Anyone using a Breathing Air Compressor should be fully trained to do so, and this will cover correct siting of a compressor.

The alternative and safest way to ensure constant complaint quality of air supply is to use a Live Air Quality Monitoring system. One such system is the AirTrack by Luno Systems, which constantly monitors the quality of air supply and will automatically switch a Breathing Air Compressor over to the back-up supply in the event that quality is compromised.

Reviews

There are no reviews yet.